Metal wire braid on hose assembly restrain the hose elongation under pressure. Hence the force due to the internal pressure is transferred to the braid. Wire diameter and total number of wires are calculated to suit the pressure rating. A second layer of braid may be used to increase pressure rating.

Braid coverage is another important criteria. Less coverage leads to hose squirm under pressure while bending. Over coverage braid does not tighten the outer diameter of hose as there is clearance between them. Braid is designed to have optimum coverage.

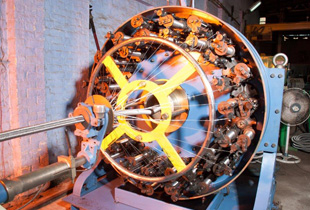

Tubular or Beam Braid:

Tubular Braid is manufactured by grouping single wires and then braiding them into basket waive pattern that tightens when braid is stretched.